|

Rotational machinery can cause undesirable noises and vibrations. Examples of this are combustion engines and electric motors, but also turbines and other motor units such as turbochargers. The overall noise emitted by rotational machinery comprises the acoustic contributions from all the various individual components like the drive shafts, gear units, bearings, belt drives and chain drives. To assign annoying noises and vibrations to the single components, the user can resort to different rotation analyses in the PAK-Software. The basic requirement for a meaningful analysis of rotational systems is an exact recording of the rotational speed using high resolution tacho inputs. At a Glance:

An order analysis with digital resampling of the measurement data allows the noise sources of rotating components to be matched with the harmonics (orders) of the rotational speed.

Changes in the rotational speed within a rotation (rotational irregularity) or distortion of a drive axle (torsion) are recorded and analyzed by means of the PAK torsional vibration analysis.

Angle-related vibroacoustic phenomena, such as those that occur during the combustion process in an engine, can be examined and identified with extreme precision using the crank angle analysis.

The PAK Combustion Analysis application is used to reconcile acoustic characteristics and combustion parameters.

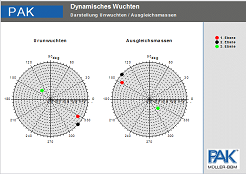

Another key task in machine diagnostics is to detect and eliminate any imbalances in a rotational system. This is done using the PAK Dynamic Balancing application, which supports multiple balancing levels. |  |